About NABAS

What is NABAS?

NABAS is the proprietary water purification system that is most efficient in

- Increasing dissolved oxygen level in water

- Creating Hydroxyl Radicals via ozone to disinfect

- Turbidity Reduction utilizing ultrafine nanobubbles as DAF (Dissolved Air Flotation)

How do Oxygen and Ozone Generators work?

Oxygen Generator

Oxygen generator takes in atmosphere air (which is about 25%-30% oxygen and 70~75% nitrogen) and separates these two (2) gases, taking only the oxygen with purity of >95%. This is done through a filtering process using zeolite which is used in every oxygen generators in the market. The distinction for NABAS is that NABAS oxygen generator does not need a reserve tank for oxygen, producing pure oxygen on demand while majority of oxygen generators in the market requires reserve tank. NABAS oxygen generators are efficient with smaller footprint.

Ozone Generator

Ozone generator require oxygen (O2) to make ozone (O3). Ozone generator takes oxygen (O2) and applies corona discharge converting O2 to O3. In ozone production, the amount and quality of oxygen has direct correlation with ozone production. Balancing these two (2) gases for maximum O3 production is one of NABAS’ trade-secrets.

There are two (2) aspects about using ozone in an aeration system: (i) ozone is corrosive over time and hence the using proper material is paramount and (ii) to have effective O3 production, oxygen generator is required to achieve both purity and volume.

i

System Construction for Ozone Usage

Unless appropriate material is utilized, such as stainless steel, the system will fail over relatively short period, unless use negligible ozone generator just to claim it is ozone technology measured in “mg/L” rather than “g/L.” NABAS utilizes “g/L” which is 1,000x more than “mg/L”

ii

Oxygen Generator for Effective Ozone

If an aeration system mentions usage of ozone, it is important to find out if oxygen generator is being used and what the capacity is (along with ozone generator capacity). Many install “mg/L” ozone generators without any oxygen generator which in the end has negligible impact in water treatment. Statement of ozone usage is “true,” but has false connotation of it’s impact.

Having both oxygen and ozone generators is important, but none of these matter if the DELIVERY system (bubbles size and quantity) is unable to implode inside the water to have dissolution.

Overview: 4 Ways to Deploy NABAS

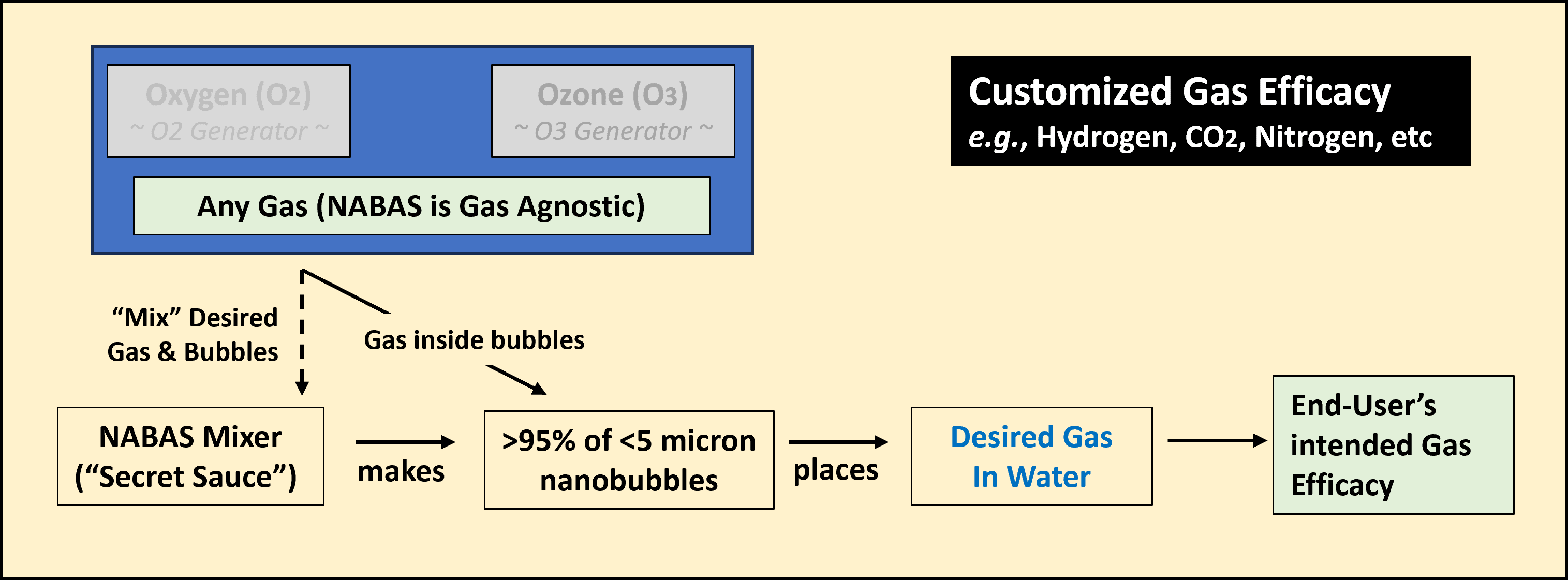

Depending on your purpose, NABAS Unit can be deployed in 4 different ways. Although standard configuration of NABAS comes with oxygen and ozone generators, each can be operated separately

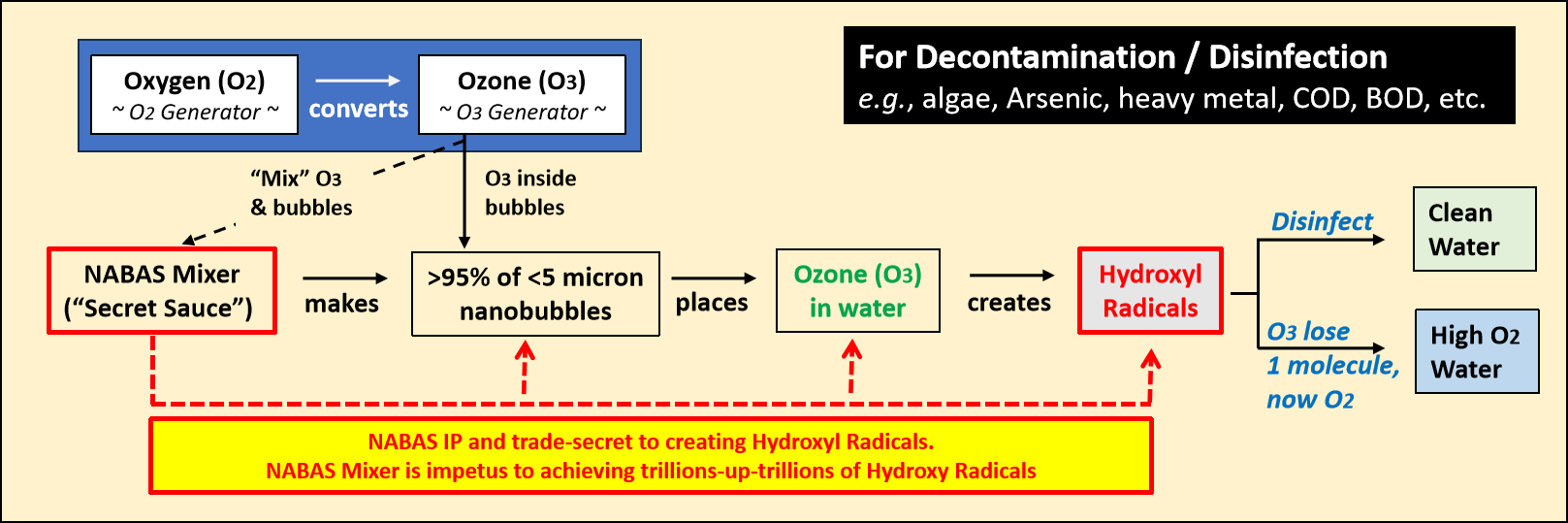

1 of 4: NABAS Mixer with Oxygen & Ozone

Goal: Decontamination / Disinfection – i.e., Hydroxyl Radicals

e.g., algae filled lakes & ponds | irrigation reserve | arsenic | heavy metal

BOD & COD Reduction, etc. (generally “wastewater” treatment)

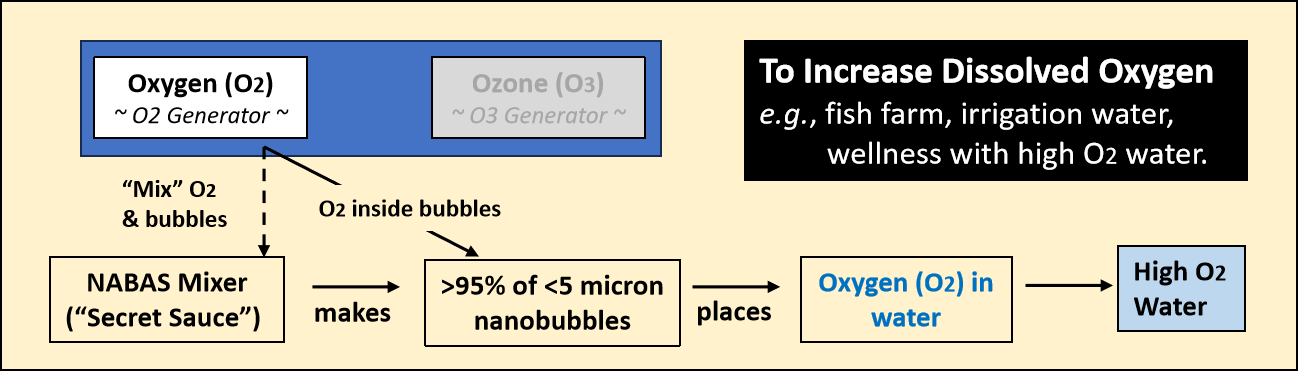

2 of 4: NABAS Mixer with Oxygen (no Ozone)

Goal: To increase Dissolved Oxygen level in water

e.g., aquafarm | irrigation water | livestock drinking water – Dairy Cow, Hog & Chicken drinking water

Wellness Bottled Oxygen Water, etc.

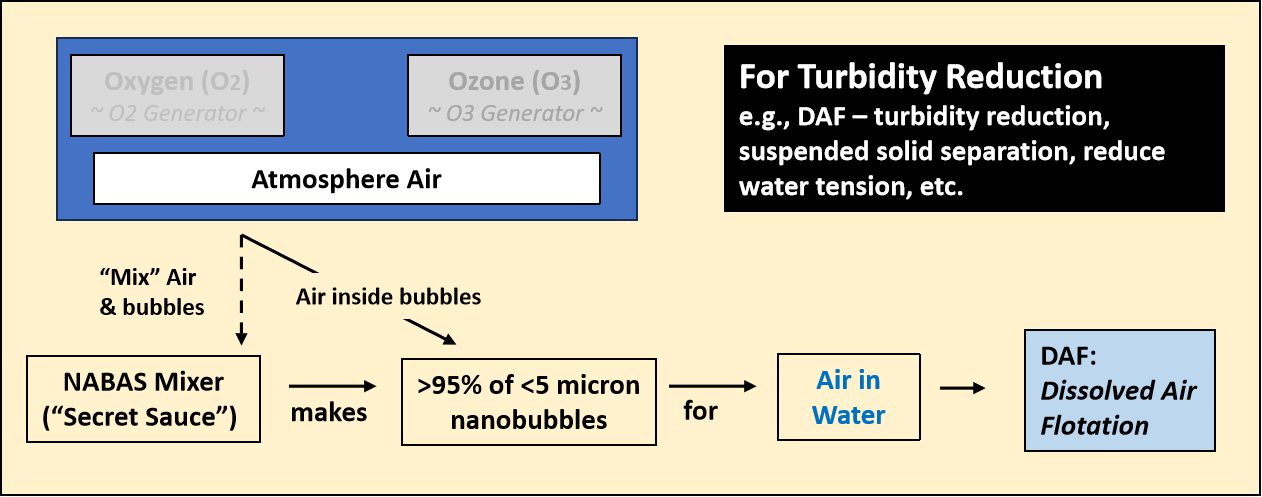

3 of 4: NABAS Mixer with atmosphere air (No Oxygen, No Ozone)

Goal: Turbidity Reduction – use as DAF (Dissolved Air Flotation)

e.g., Suspended Solid Separation (DAF) | Wastewater Treatment Plants, | Water Tension Reduction

NABAS & Hydroxyl Radicals

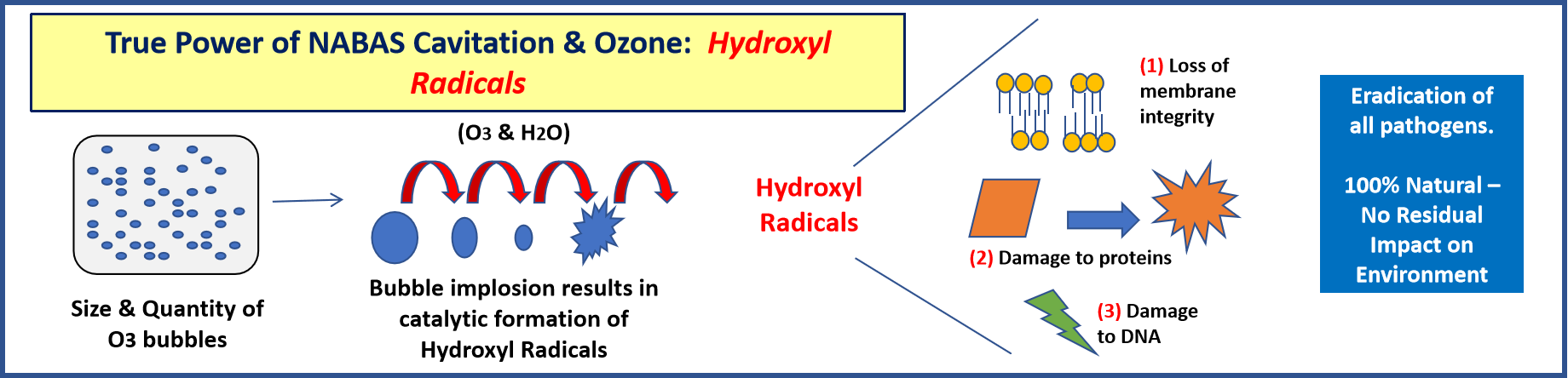

Hydroxyl Radical (also known as “OH Radicals” as in “Oxygen” and “Hydrogen”) is a process in which O3 filled nanobubbles implode, creating two (2) energies: HEAT & SONIC energies

- ~ Heat Energy of 5,000-degree Celsius(or 9,032 Fahrenheit)

- ~ Sonic Energy of 40KHz Ultra Sonic Waves

Hydroxyl Radicals, by creating heat and sonic energy as bubbles implode from the pressure of water, shatters and shreds single-cell organisms’ outer shells and attack the nucleus. This is where QUANTITY (not just the SIZE) is important to have wide coverage in the entire water-column (and not rise to surface). This implosion (or explosion) is only for nanoseconds and as O3 goes through this chaotic state, O3 loses one (1) molecule, becoming O2 (thereby NABAS simultaneously disinfects and increases oxygen level). As proven at a lab and in situ operation, the impact of Hydroxyl Radicals last 72 hours after NABAS operation stops. Hydroxyl radical is so strong, they penetrate biofilm (which is 1,000x more resistant to environmental change and many are impervious to chemicals) and destroy the colony of pathogens inside (and once again, QUANITY is crucial in this process).

As Hydroxyl Radicals has one of highest oxidation power, NABAS oxidizes heavy metal instantaneously. Where there is soluble iron present in water, the water turn red which allows iron to be filtered out which other could not before NABAS. Through NABAS process, >90% of heavy metal, such as iron, can be removed.

Hydroxyl Radical & ORP (Oxidation Reduction Potential)

The summary of NABAS’ Hydroxyl Radicals in terms of ORP, please see below.

SUMMARY: Hydroxyl Radicals (aka OH Radicals)

Hydroxyl Radicals (aka OH radicals) are formed when ozone is introduced into the NABAS Mixer as water is being shredded, filling trillion-upon-trillion of ultrafine nanobubbles with ozone. In this chaotic state, ultrafine nanobubbles are introduced into water and than they implode, creating heat and sonic energy to destroy biological contaminants. During this implosion, trillion-upon-trillion ozone (O3) loses one (1) molecule and all O3 gases becomes O2, oxygen.

Hydroxyl Radicals is able to perform multiple functions at the same time, as shown below on the NPWS (NABAS Potable Water System) video:

- 1- Eradicate single-cell organisms

- 2- Effectively Break through bacteria biofilm to eradicate pathogens (where many chemicals have no or little impact)

- 3- Crystalize (or rust) otherwise unfilterable soluble metal (e.g., iron and manganese) to be filtered out

- 4- Turbidity Reduction (DAF): Lift suspended solids (SS) in water column to the surface as ultrafine nanobubbles are “negatively charged” while SS in water are “positively charged.” Positively charged SS attract negatively charged NABAS ultrafine nanobubbles, creating buoyancy to be lifted to the surface

- 5- Increase dissolved oxygen level in water

NABAS’ “secret sauce” is the Mixer… but the “secret weapon” is the Hydroxyl Radicals

1

What is the PROBLEM that needs solving?

2

3

NABAS Technology Offering

NABAS technology offering comes in two (2) formats:

- 1) Standard “N” and “NB” models.

- 2) Customized “NSA” – NABAS Solution Architect

Standard “N” and “NB” Models

Which NABAS Unit?

While NABAS units are based on flow rate, treatment impact analysis is based on “dosage of Hydroxyl Radicals and/or oxygen.” The flow rate is used to calculate “time” of treatment with initial calculation of 1x turnover as a baseline. Once the 1x turnover baseline has been established, depending on the (i) contamination level of source water and (ii) purpose of treatment, NABAS “dosage” can be calculated.

Here is an example of calculation based on “dosage” of Hydroxyl Radicals (O3) and/or oxygen (O2) for the purpose of aesthetics at a golf course by eradicating algae. While the “dosage” is 30% at a golf course, if this were to be for irrigation with increased dissolved oxygen level to 25 mg/L, the “dosage” would be much higher in terms of treatment time. This is a demonstration on HOW to calculate which NABAS unit is suited for the desired result of treatment.

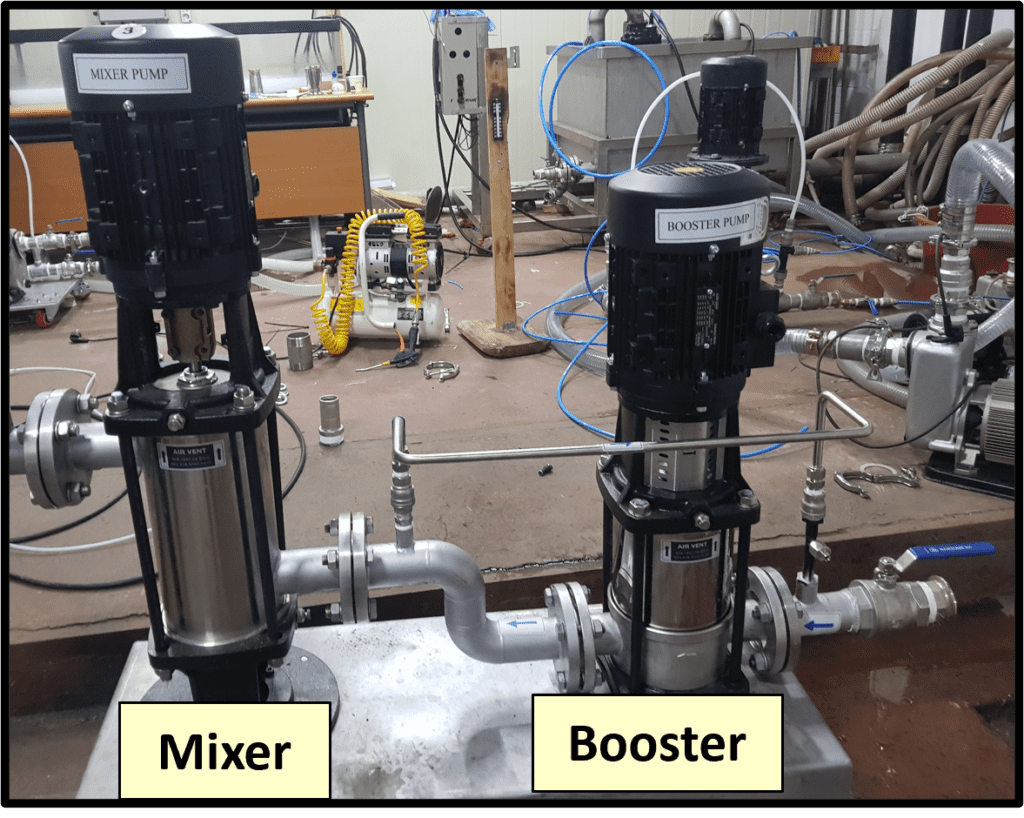

NABAS has two (2) standard models: “N” & “NB”

“N” Model

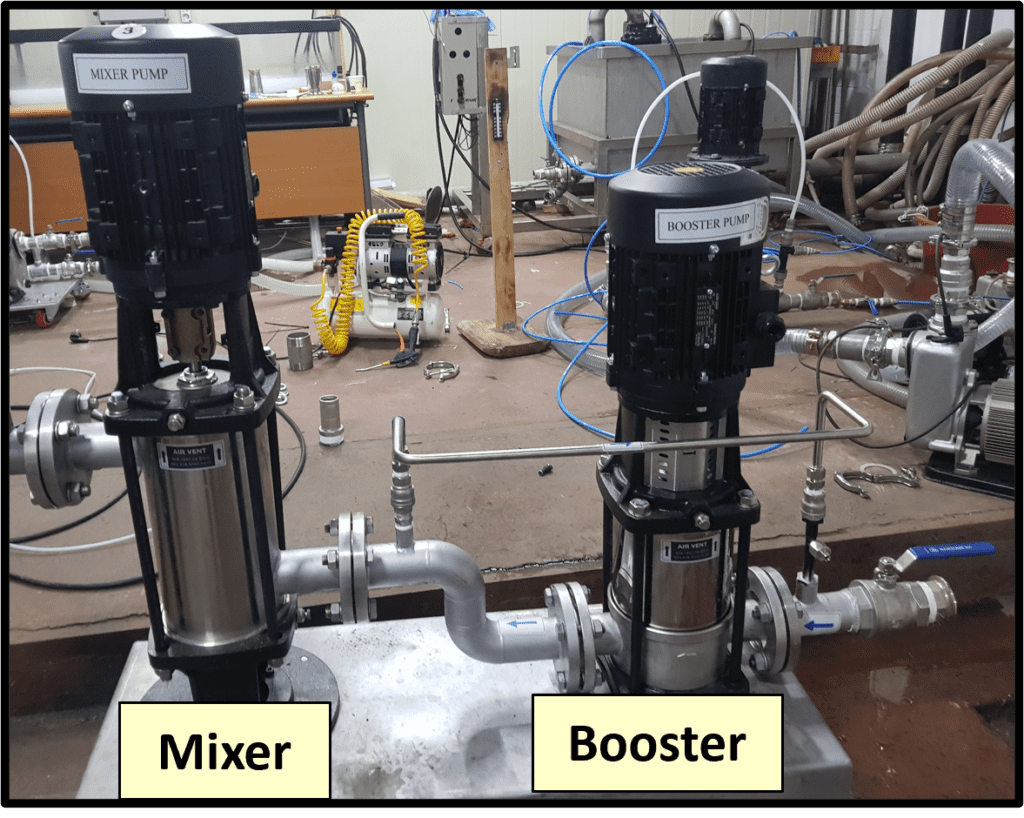

“N” Model has Mixer with O2 and O3 Generators – N-5 & N-15

“NB” Model

“NB” Model has Mixer & Booster with O2 and O3 Generators (NB-30 & NB-50)

Due to scalability of NABAS, instead of 1x NB-30, for example, implement 2x N-15.

This allows for redundancy and also ability to deploy multiple locations as needed.

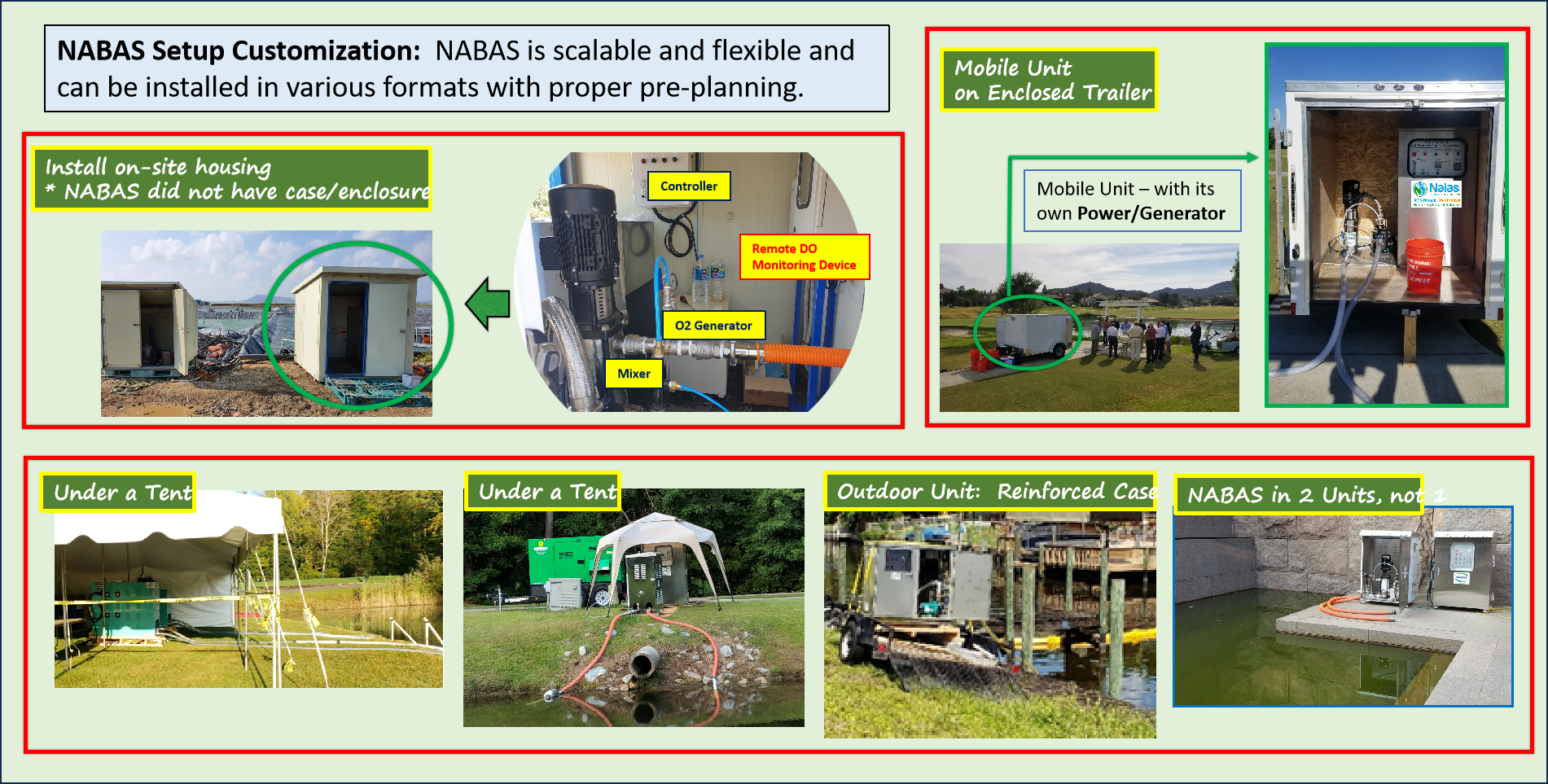

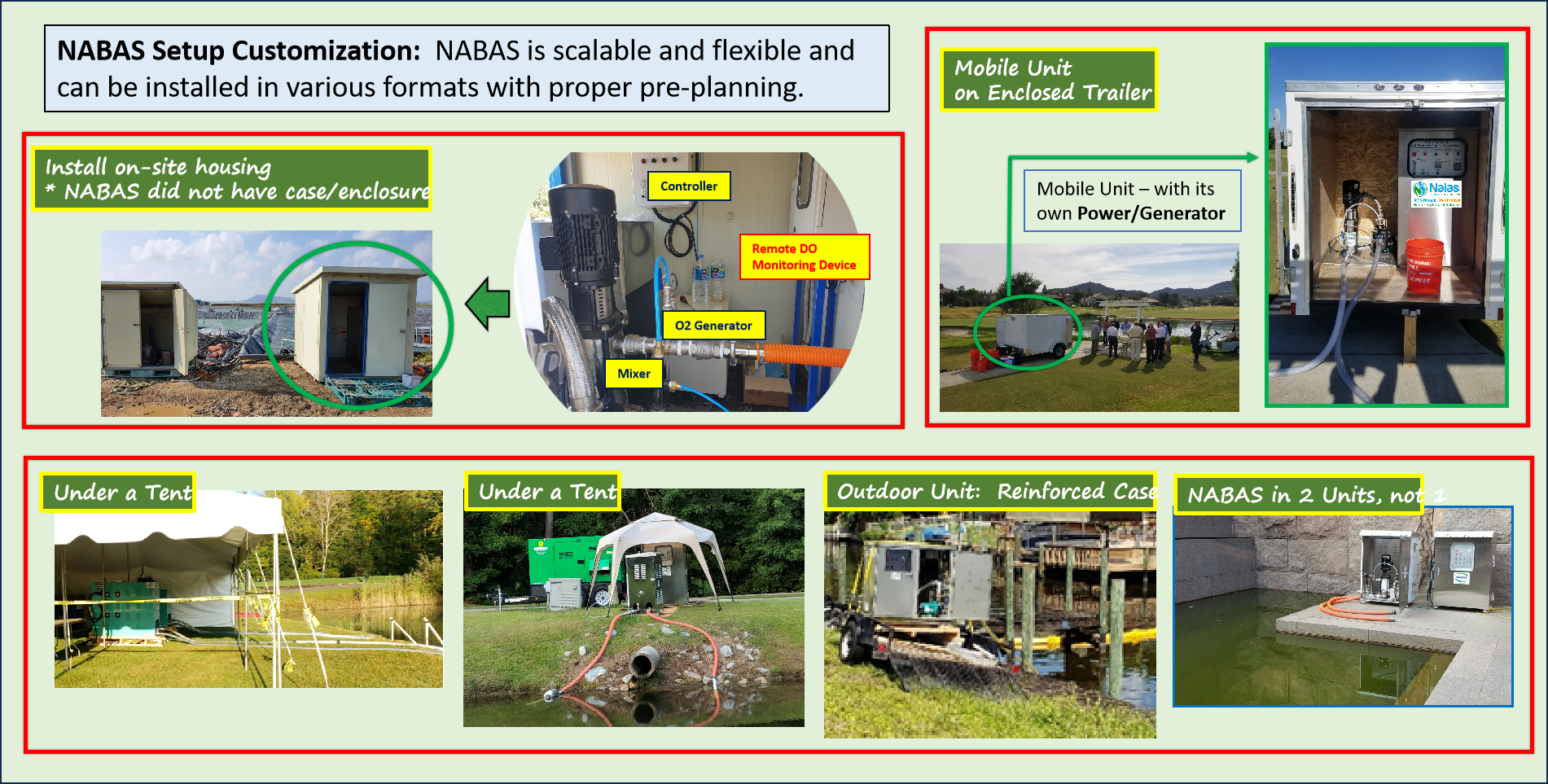

NABAS “N” and “NB” model configuration can be modified and customized per environment.

NABAS Solution Architect

Based on NABAS’ 4 methods of deployment (see above), a water solution architect is designed, collaborating with other technologies.

NPWS – NABAS Potable Water System

Aquifer-to-Potable Water

PROBLEM: Arsenic-III & Heavy Metal

Wastewater Pre-treatment

Dairy Farm Wastewater treatment

PROBLEM: BOD, COD, SS, T-N

Sediment Remediation

Improve Waterway Quality

PROBLEM: Contaminated Sediment

NABAS Solution Architect’s center piece is NABAS with supporting technologies. Think about a SitCom of “Seinfeld.” Seinfeld is the main character, but Seinfeld could not have reached pinnacle of its success without the supporting characters. However without Seinfeld himself, there is no “Seinfeld” show. Similarly collaborative technology allows NABAS Solution Architect to be great, however without NABAS, desired solution cannot be reached.

While NABAS is not the only solution available, in almost all cases, NABAS is a better option to pursue that traditional chemical methods.

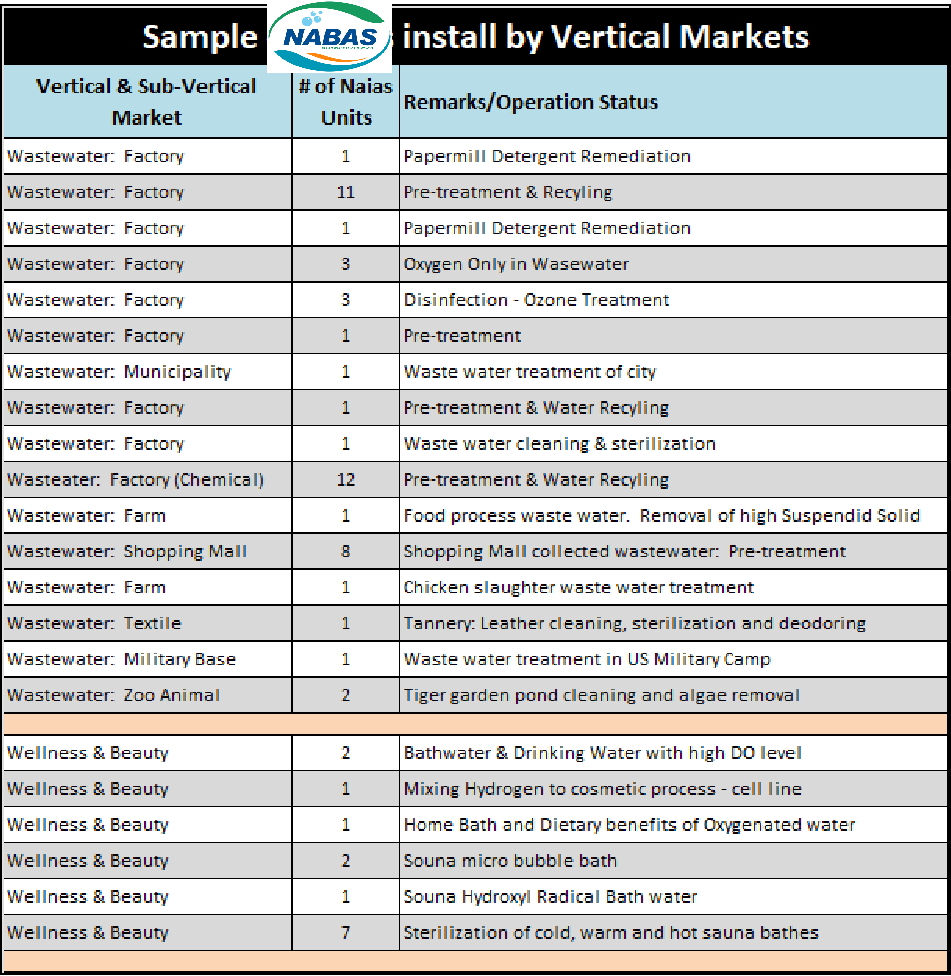

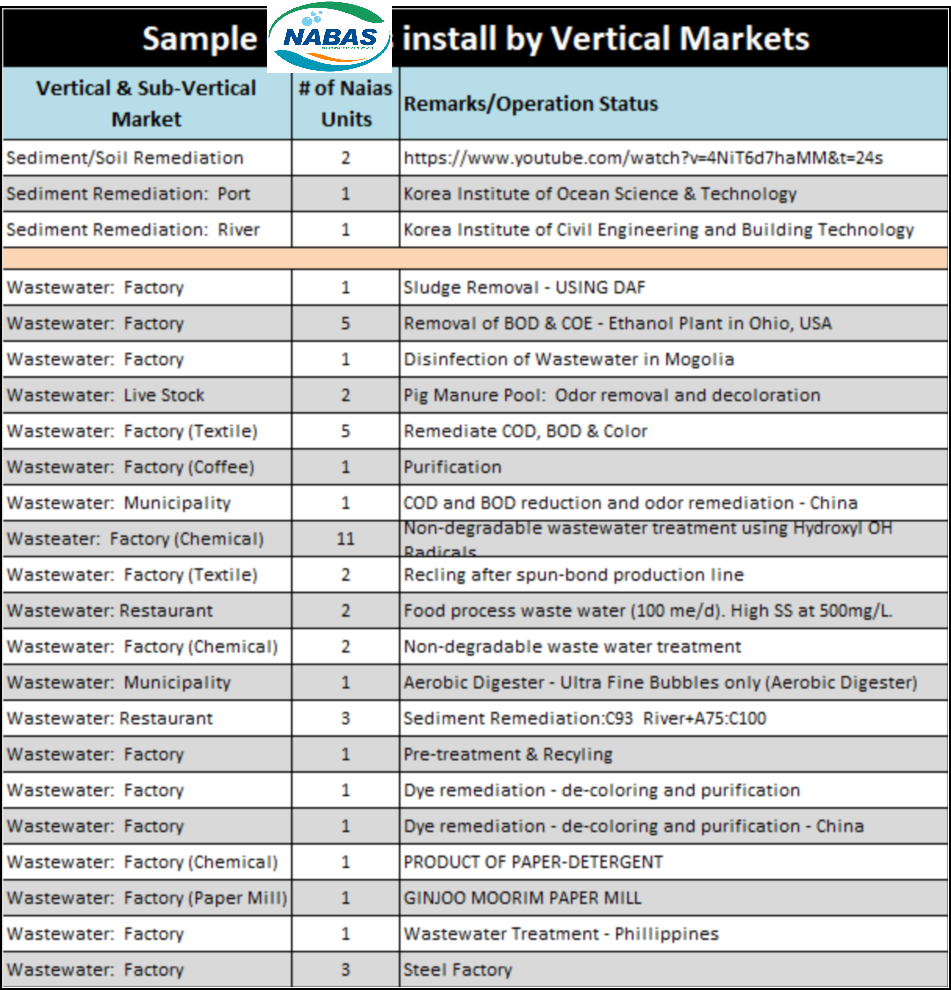

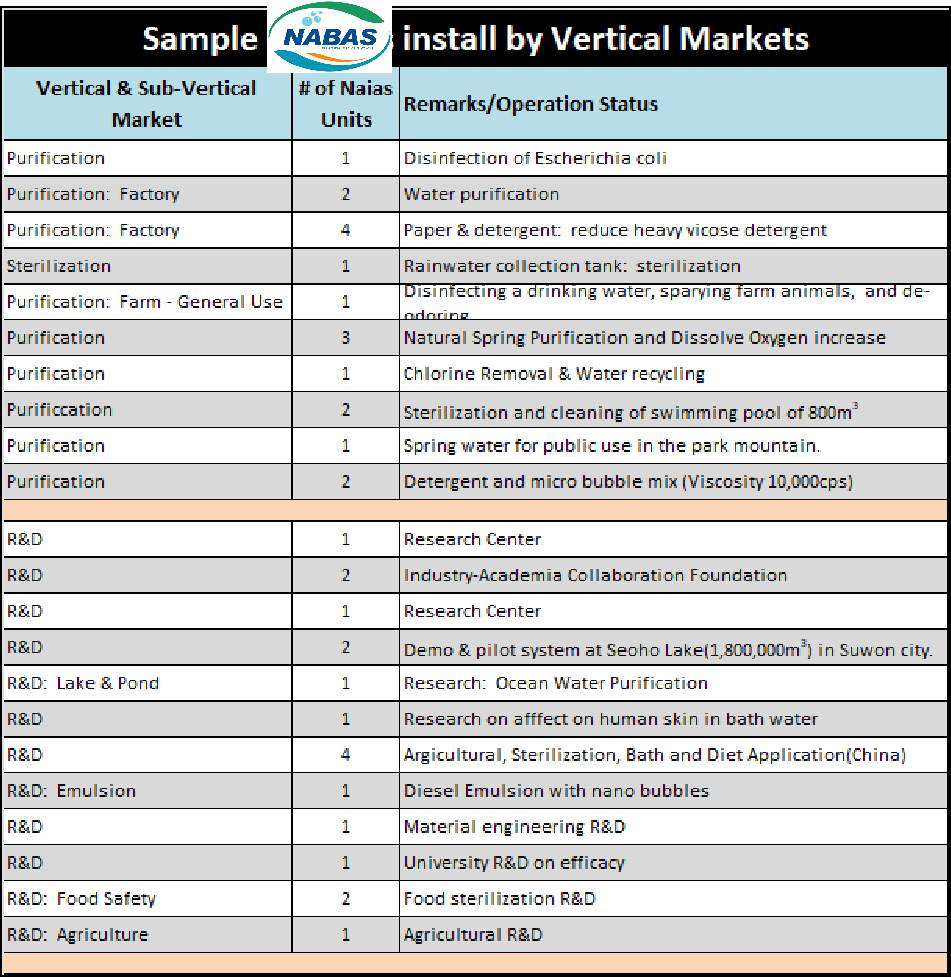

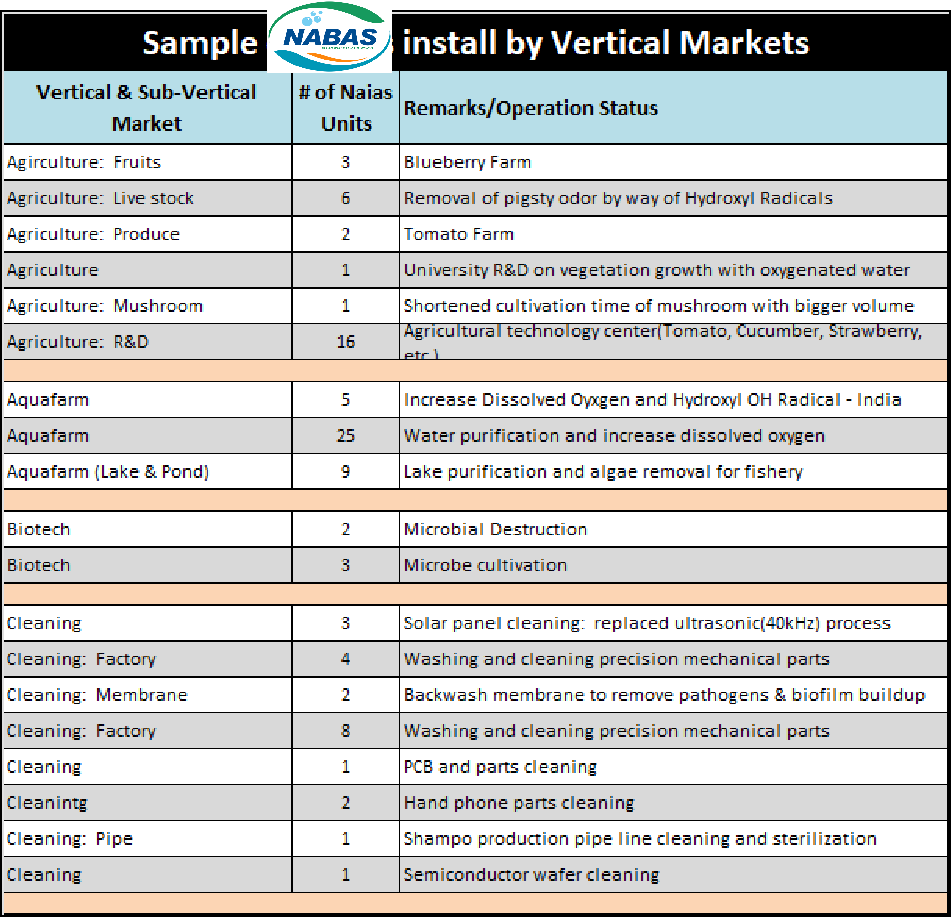

VERTICAL MARKETS: NABAS Technology Offering

NABAS “secret sauce” is the Mixer and its “secret weapon” against contaminated water is Hydroxyl Radicals along with increasing dissolved oxygen level and improving turbidity.

What can you do with NABAS’ “secret sauce” and “secret weapon”?

The following are the list of some vertical markets and HOW NABAS was implemented.

NABAS Group 2024 | All Rights Reserved